© Copyright 2025 by 240 Tech, LLC | Sitemap

FAQs

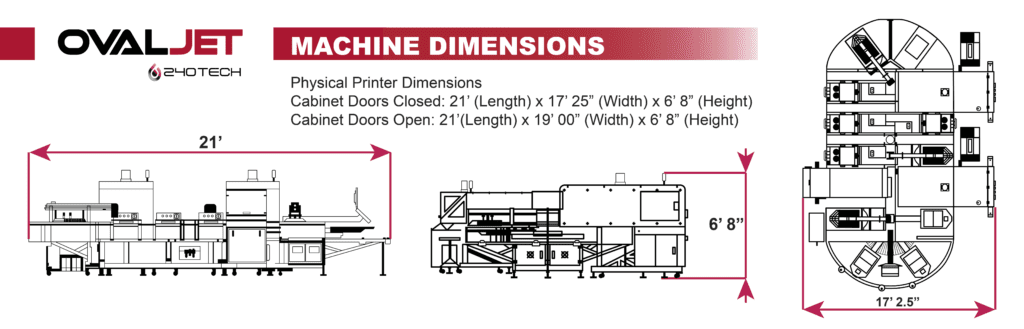

The OvalJet physical printer dimensions with the cabinet doors closed are 21 ft (Length) x 17 ft 25 in (Width) x 6 ft 8 in (Height). The dimensions with the cabinet doors open are 21 ft (Length) x 19 ft (Width) x 6 ft 8 in (Height). It is recommended that there is 3 – 5 ft of space between the OvalJet loading/unloading zone and the dryer, then 5 ft of space added to other sides of the machine to allow room for walkways and maintenance.

Your warehouse space should be temperature controlled 68 – 82 degrees F with 50 – 80% relative humidity. Temperature and humidity ranges can be achieved with air conditioner and humidifier systems. Electrical requirements include incoming power of three phase 208v AC and 200 total amps. Compressed air will require 100 PSI :: 7 bad.

- The OvalJet indexes at 240 prints an hour for a full-size print of 16 x 19 in plus 3 x 4 neck label, and a resolution of 800 x 2400 DPI (8 Pass). Our current customers produce an average of 180-200 prints per hour resulting in lower system operating costs, lower labor costs and the best return on investment of all high speed DTG printers.

- View our Speed Test Video to see the OvalJet in a production environment. This video shows speed tests for four different garment runs including mixed media (large and small sizes) and hoodies with pockets.

- Caldera raster image processor (RIP) software is included in purchase of an OvalJet system. The Caldera RIP software has been optimized for the OvalJet high-speed DTG printer. Customers can store ripped files in the cloud or RIP on-demand based on the operation.

- Turbine OMS/WMS Software is sold separately as a SaaS product and not mandatory for OvalJet operation.Full end-to-end print on demand software managing incoming orders, inventory, production, fulfillment, quality and shipping; designed for a single or multiple OvalJet locations.

The OvalJet Direct to Garment Printer System warranty period is one (1) year. This warranty extends only to the original purchaser and is non-transferable.

The OvalJet inks are optimized for superior colorfastness and wash durability; finest print detail and color gradations; bright whites (L=93+) and the largest color gamut attained with 6-color plus white (Cyan, Magenta, Yellow, Key, Red, Green, and White). Our water based inks can cure with dwell time of approximately 3 – 4 minutes in a conveyor dryer at 300 degrees F.

Upon install, 240 Tech – OvalJet Service Technicians will train the future OvalJet Operators on a standard operating procedure (SOP) that includes use and maintenance of an OvalJet. Operators will learn how to perform daily, weekly, and monthly maintenance during the install. Our Service department will also invite customers to join live monthly trainings that are recorded and shared for customer use.

Like many DTG printers, fabric type is key to a successful print. The OvalJet DTG printer performs best on textiles with natural fabric and blends with a higher percentage of natural fabric to synthetic fabrics.

Natural textiles work best because of it’s ability to absorb the water-based ink of a DTG printer. Synthetic fabrics are composed of plastics, which repel the water-based ink.

Common natural fibers include cotton, combed cotton, and organic cotton. Common synthetic fibers include polyester and nylon. Common natural and synthetic fabric blends include a cotton, polyester, rayon triblend and a cotton/polyester biblend.